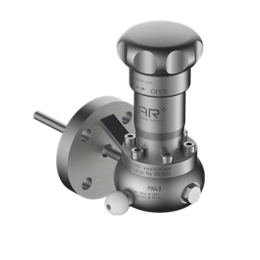

PRIMARY AND MAIN PROTECTION GUARANTEEING THE SAFETY OF THE SAMPLING POINT

BIAR offers three designs of stem gaskets with materials that can be adapted to the required temperatures, sampling pressures and rackings. These O'rings have been specially designed to withstand temperatures from -40 to +400°C (-40 to 752°F) as well as pressures from 0 to 100 bar (0 to 1450 psi).

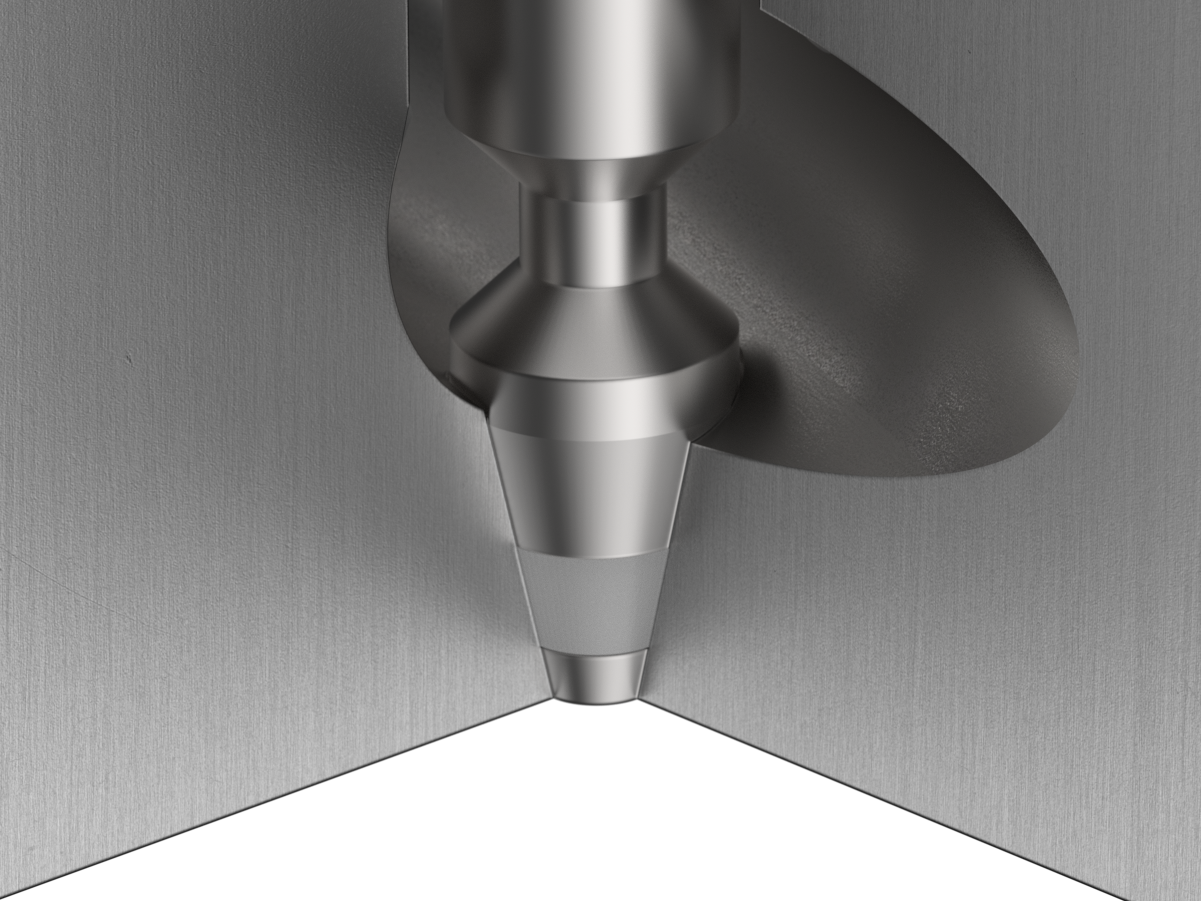

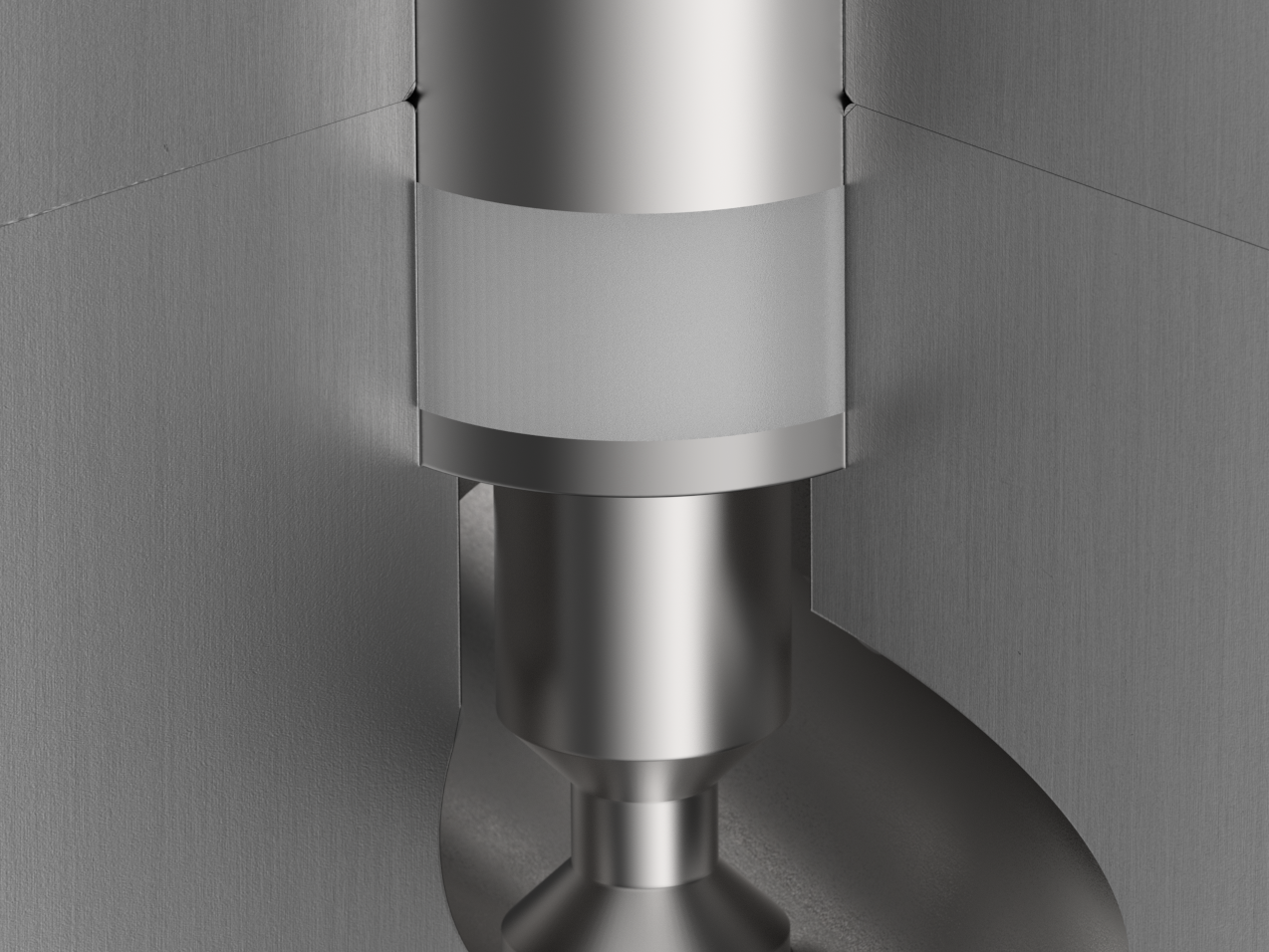

Standard stem gasket

The Standard stem gasket is initially available in PTFE and can also be provided in Carbon PTFE or PEEK, depending on the sampling parameters. Both the PTFE and PEEK variants comply with FDA regulations.

Applications

- Suitable for most applications

- Liquids with few or no particles

- In PTFE and PEEK, suitable for the food industry

- Temperatures from -40°C (-40°F) to 280°C (536°F)

- Pressures up to 16 bar (232 psi)

Advantages

- Perfect sealing at low pressures and temperatures

- Highly satisfactory chemical resistance, particularly in PTFE

- Excellent durability

- Simple, low maintenance

- Simple, low maintenance

Configure your standard stem gasket