Hydrofluoric acid (HF) sampling IN refinery alkylation units

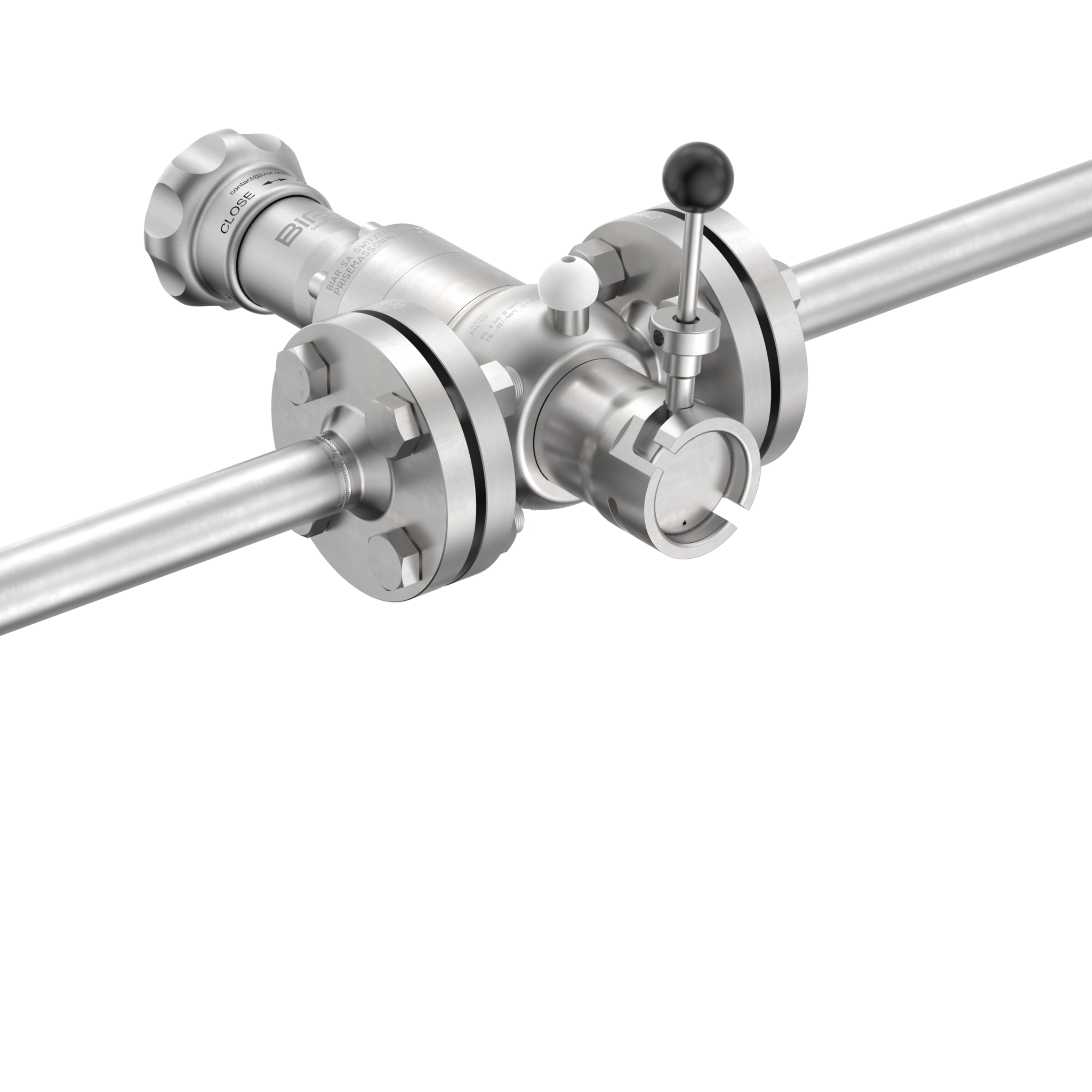

Hydrofluoric acid (HF) is an essential catalyst in the refinery alkylation process (HFA), a crucial step in the production of high-octane hydrocarbons. However, handling HF requires rigorous monitoring to ensure safe and efficient operations. BIAR SA offers hydrofluoric acid sampling solutions specially designed to meet the specific challenges of HFA alkylation units.

- Enhanced safety during HF alkylation

Precise control of HF concentration is imperative to prevent the risk of system runaway, thus ensuring the safety of installations and personnel. - Optimizing the alkylation process

Humidity control is crucial to maximize alkylation efficiency and prevent equipment corrosion. - Too low an HF concentration can be extremely dangerous, increasing the risk of system runaway.

- Conversely, water levels that are too low degrade alkylation efficiency, while water levels that are too high accelerate equipment corrosion.

HF sampling: Key to alkylation efficiency and safety

Rigorous sampling of hydrofluoric acid (HF) is essential for optimum control of the refinery alkylation process. The performance of this process, crucial to the production of high-octane gasoline, depends on critical parameters such as HF concentration, moisture content and acid-soluble oil (ASO) content. A reliable and accurate sampling program allows you to :

- Optimize alkylation efficiency: Precise parameter monitoring ensures maximum process performance.

- Ensure consistent product quality: Sampling helps maintain consistent hydrocarbon quality

- Reduce hydrofluoric acid (HF) consumption : Precise control limits losses and optimizes catalyst utilization.

- Improve refinery profitability : Process optimization and cost reduction contribute to greater profitability.

- Enhance operational safety: Rigorous monitoring of parameters minimizes the risk of incidents related to HF handling.

- Prevent equipment corrosion: Precise control of moisture and ASO content protects installations.

Critical parameters for hydrofluoric acid (HF) analysis

Accurate analysis of hydrofluoric acid (HF) samples is essential to guarantee the efficiency and safety of the alkylation process. Two parameters are of particular importance:

- Moisture content

- Acid-soluble oil (ASO) content